Glass tempering is a critical process in the manufacturing of sealed glass units, with profound effects on the properties and performance of the final product. Understanding the tempering process is essential for businesses in the window manufacturing, glazing, and glass shop industries. In this article, we'll take a look at the impact of the tempering process on glass, exploring its environmental sustainability, enhanced properties, scientific underpinnings, and future trends.

Environmental Sustainability in Tempered Glass Production

The production of tempered glass aligns with sustainable practices, offering significant environmental advantages.

Energy Efficiency: The tempering process is notably energy-efficient, requiring less energy compared to the production of standard glass. This reduced energy consumption contributes to lower greenhouse gas emissions, making tempered glass a favorable choice for environmentally conscious businesses.

Material Waste Reduction: Tempering minimizes material waste by enhancing the strength and durability of glass, thereby reducing the need for frequent replacements. This results in decreased waste generation and a more sustainable approach to glass manufacturing.

The environmental impact of tempered glass production is substantial, with energy efficiency and waste reduction playing pivotal roles in promoting sustainable production practices.

Comparing Pre and Post-Tempering Glass Properties

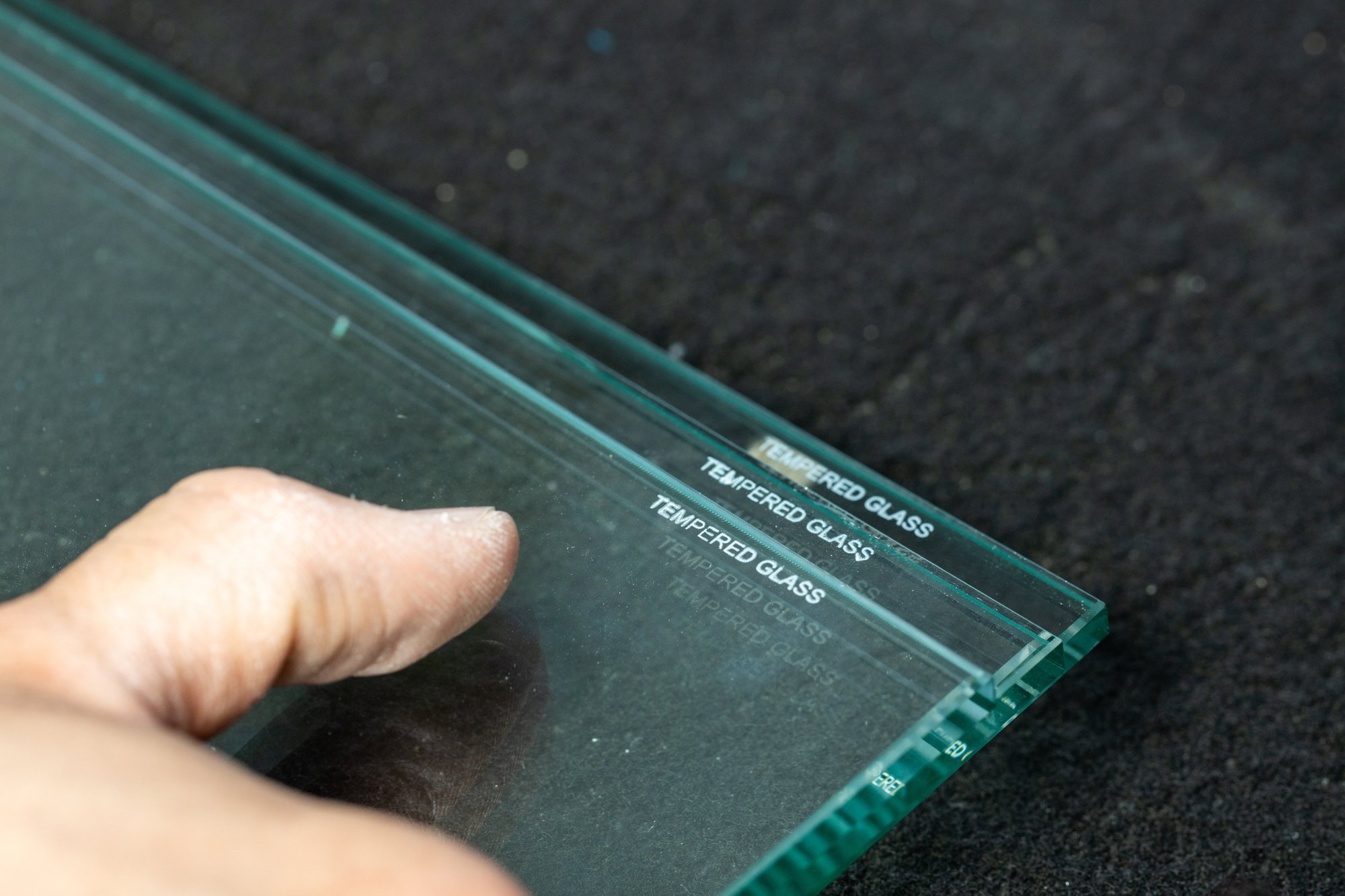

Tempered glass exhibits remarkable differences in properties compared to standard glass, making it a superior choice for various applications.

Enhanced Strength: The tempering process significantly increases the strength of glass, making it more resistant to external forces and impacts. This enhanced strength is particularly beneficial in architectural and automotive applications, where safety and durability are paramount.

Resistance to Thermal Stress: Tempered glass demonstrates exceptional resistance to thermal stress, allowing it to withstand rapid temperature changes without compromising its structural integrity. This property is crucial in environments with fluctuating temperatures, such as building facades and oven doors.

Safety Features: When tempered glass breaks, it shatters into small, granular pieces instead of sharp shards, reducing the risk of severe injuries. This safety feature makes tempered glass an ideal choice for applications where human interaction is prevalent, such as shower enclosures and glass doors.

The tempering process profoundly enhances the mechanical and thermal properties of glass, making tempered glass a versatile and reliable material for a wide range of industrial and commercial uses.

Unveiling the Science Behind Glass Transformation

The tempering process induces profound structural changes in glass, resulting in its exceptional strength and safety characteristics.

Ion Exchange: During tempering, the glass surface is placed under compression through ion exchange, where smaller ions are forced into the glass surface, creating a state of high compression. This process significantly enhances the glass's resistance to mechanical stress and impact.

Uniform Cooling: After the ion exchange process, the tempered glass is uniformly cooled, creating a balanced internal stress distribution. This equilibrium contributes to the glass's ability to withstand thermal differentials without fracturing, a crucial property in various applications.

Surface Compression: The tempering process induces surface compression, which is essential for the safety features of tempered glass. When the glass experiences an impact, the stored energy in the compressed surface layer causes the glass to disintegrate into small, granular pieces, reducing the risk of severe injuries.

The intricate scientific principles behind the tempering process underscore the exceptional strength and safety characteristics of tempered glass, making it an indispensable material in modern industrial and architectural applications.

Exploring Innovations and Future Trends

Glass tempering technology continues to evolve, paving the way for enhanced glass performance and sustainability.

Advanced Heating and Cooling Methods: Innovations in tempering technology are focused on optimizing the heating and cooling processes, leading to improved glass strength and reduced energy consumption. Advanced heating methods, such as convection heating, and precise cooling control contribute to the production of tempered glass with superior properties.

Incorporation of Nanotechnology: The integration of nanotechnology in the tempering process holds promise for further enhancing the mechanical and thermal properties of glass. Nanoparticles can be incorporated into the glass surface during tempering, resulting in increased strength and resilience, opening new frontiers for glass applications.

Sustainability Initiatives: Future trends in glass tempering emphasize sustainability, with a focus on reducing energy consumption and minimizing environmental impact. The development of eco-friendly tempering processes and the use of recyclable materials in glass production are key areas of innovation in the industry.

These advancements in glass tempering technology signify a shift towards more sustainable and high-performance glass solutions, offering businesses in the window manufacturing, glazing, and glass shop industries access to innovative and eco-conscious materials.

The tempering process stands as a cornerstone of the glass industry, offering enhanced strength, safety, and sustainability. From its environmental benefits to the transformative effects on glass properties, the significance of tempering cannot be overstated. As businesses seek reliable and high-performance glass solutions, understanding the tempering process becomes imperative.

Embracing the advancements and principles of tempered glass manufacturing is key to driving innovation and sustainability in the industry. For those looking to explore top-tier sealed glass units and custom-sealed units, Insul-Lite Manufacturing provides a comprehensive range of products and information.