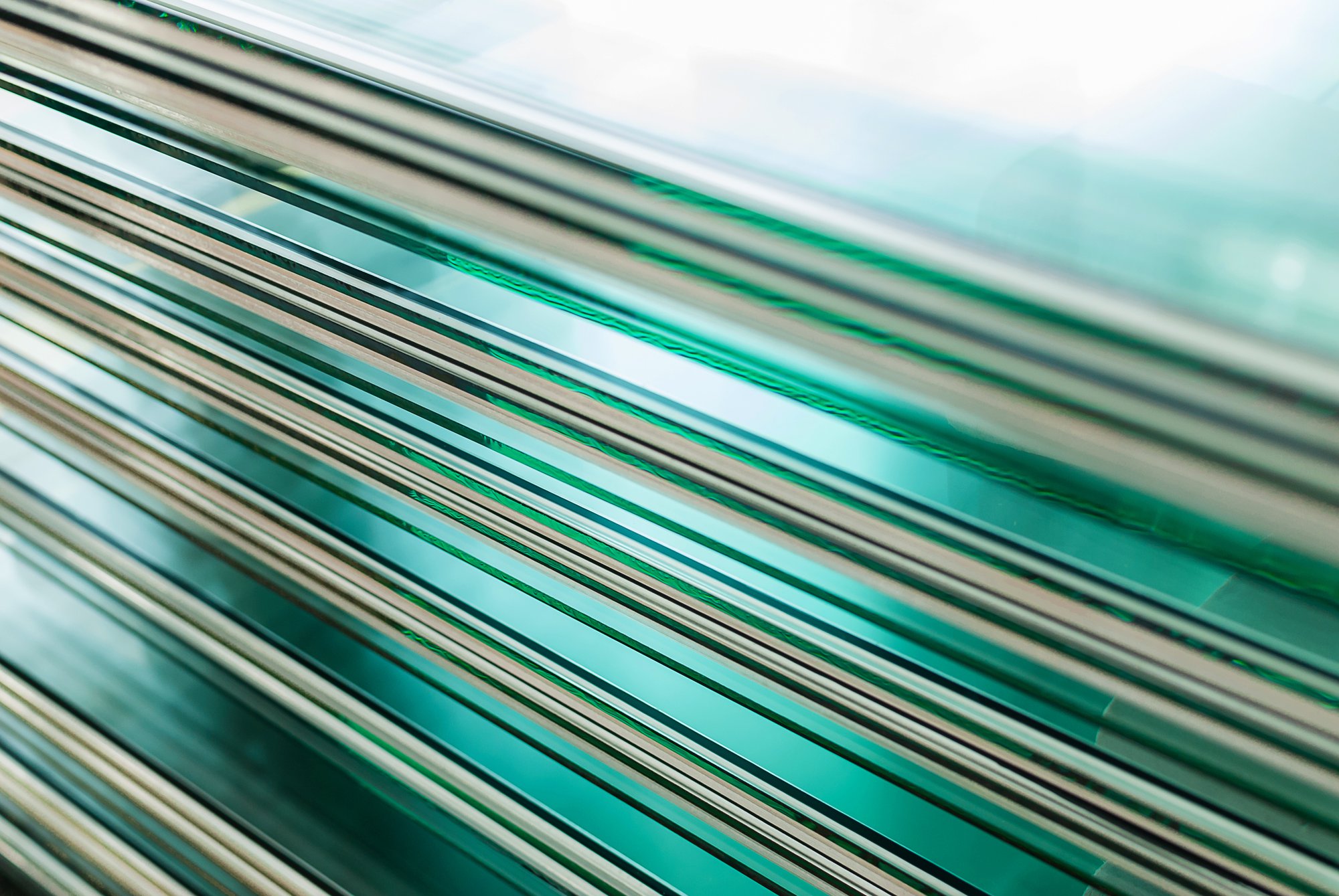

How are technological advancements in protective film application transforming the glass industry? Recent innovations in protective film materials are revolutionizing the way we think about glass protection. These advancements not only enhance durability and functionality but also contribute to energy efficiency and environmental sustainability. This article explores the latest developments in protective film technology and their practical applications across various sectors.

The Revolution in Protective Film Application

Technological advancements in protective film materials are reshaping the glass industry. Nanotechnology, for instance, has introduced films with enhanced strength and flexibility. These films can withstand extreme conditions, providing superior protection against scratches and impacts. Smart films, another innovation, offer dynamic functionalities such as adjustable opacity and UV filtering.

Nanotechnology-based films incorporate nanoparticles that enhance the film's properties. These particles improve the film's resistance to wear and tear, extending the lifespan of glass surfaces. Additionally, smart films can be controlled electronically, allowing users to switch between transparent and opaque states. This feature is particularly useful in commercial buildings where privacy and light control are essential.

The practical implications of these innovations are significant. For window manufacturers, the use of advanced protective films means fewer replacements and repairs. Glazing contractors benefit from the ease of installation and maintenance. Glass shops can offer customers a wider range of high-performance products, meeting diverse needs and preferences.

Energy Efficiency and Environmental Impact

Modern protective films significantly enhance energy efficiency and environmental sustainability. These films reduce heat transfer, leading to lower energy consumption for heating and cooling. Studies show that high-quality protective films can significantly reduce energy costs. This reduction translates to substantial savings for both residential and commercial buildings.

Eco-friendly film materials are gaining traction in the market. These materials are often made from recyclable components, minimizing environmental impact. For example, some films use biodegradable polymers that break down naturally over time. This innovation aligns with global sustainability goals and reduces the carbon footprint of glass products.

In addition to energy savings, protective films also contribute to environmental conservation. By extending the lifespan of glass surfaces, they reduce the need for frequent replacements. This longevity decreases the demand for raw materials and lowers waste production. Consequently, the glass industry can achieve greater sustainability and operational efficiency.

Enhancing Durability and Safety

Advanced protective films play a crucial role in enhancing the durability and safety of glass surfaces. These films add an extra layer of strength, significantly reducing the risk of breakage. Studies indicate that protective films can decrease glass breakage. This reduction is vital for high-traffic areas and buildings exposed to harsh weather conditions.

Safety enhancements are another key benefit. Protective films can hold shattered glass together, preventing dangerous shards from causing injuries. This feature is particularly important in environments like schools, hospitals, and commercial buildings. Additionally, some films offer fire-resistant properties, adding another layer of protection.

Industry-specific terminology highlights the technical advantages. For example, "laminated safety glass" refers to glass treated with protective films that meet stringent safety standards. These films also comply with various building codes and regulations, ensuring that installations are both safe and legal. By investing in advanced protective films, businesses can enhance both the safety and longevity of their glass installations.

Cost-Benefit Analysis for Manufacturers

The financial advantages of using protective films are compelling for manufacturers. Initial costs may seem high, but the long-term savings are substantial. Protective films reduce the need for frequent glass replacements and repairs. This reduction in maintenance costs can lead to savings of up to 40% over the lifespan of the glass.

A cost-benefit analysis reveals specific ratios. For instance, the initial investment in protective films might be $5 per square foot. However, the long-term savings, including reduced energy costs and maintenance, can amount to $15 per square foot. This 3:1 cost-benefit ratio demonstrates the financial viability of protective films.

Case examples from window manufacturers further illustrate these benefits. One manufacturer reported a decrease in warranty claims after implementing protective films. Another noted an increase in customer satisfaction due to the enhanced durability and safety of their products. These examples highlight the practical and financial benefits of adopting advanced protective films.

Practical Applications Across Sectors

Protective films find diverse applications across various sectors. In commercial buildings, these films enhance energy efficiency and provide privacy. For example, office buildings use smart films to control light and reduce glare. This improves employee comfort and productivity.

In residential homes, protective films offer security and energy savings. Homeowners install these films to prevent break-ins and reduce UV damage to interiors. Additionally, energy-efficient films lower heating and cooling costs, making homes more sustainable.

The automotive industry also benefits from protective films. Car manufacturers use these films to improve windshield durability and passenger safety. For instance, films can prevent shattering during accidents, reducing injury risks. Furthermore, UV-blocking films protect vehicle interiors from sun damage, extending the lifespan of upholstery and dashboards.

The Future of Protective Film Application

Technological advancements in protective films are transforming the glass industry. Innovations like nanotechnology and smart films enhance durability, safety, and energy efficiency. These films offer significant financial benefits, reducing long-term costs for manufacturers. Their diverse applications across commercial, residential, and automotive sectors highlight their versatility. As ongoing innovations continue to emerge, the potential for protective film applications will only grow. Embracing these advancements will lead to safer, more efficient, and sustainable glass solutions.

Visit Insul-Lite Manufacturing to learn more about how our advanced protective films can meet your specific needs and contribute to a more sustainable future.