Low-E coatings offer a transformative solution for reducing energy costs, enhancing indoor comfort, and promoting environmental sustainability. By improving the thermal performance of windows, these advanced coatings help maintain consistent indoor temperatures, minimize heat loss, and reduce cold drafts. This leads to significant energy savings and contributes to a lower carbon footprint, aligning with broader sustainability goals.

Enhancing Indoor Comfort with Advanced Technology

Low-E coatings significantly enhance indoor comfort by maintaining consistent indoor temperatures throughout the year. These coatings reflect infrared light, keeping heat inside during the winter and outside during the summer. This thermal regulation reduces the need for constant heating and cooling, leading to a more stable and comfortable indoor environment.

Furthermore, low-E coatings effectively reduce cold drafts that often make indoor spaces uncomfortable. By minimizing heat loss through windows, these coatings ensure that the warmth generated inside stays inside. This is particularly beneficial in colder climates, where maintaining a warm indoor temperature is crucial for comfort.

In addition to reducing cold drafts, low-E coatings also minimize heat loss, which is a common issue in buildings with large window areas. The advanced technology used in these coatings creates a barrier that prevents heat from escaping, ensuring that indoor spaces remain warm and cozy. This enhances comfort and contributes to energy efficiency by reducing the need for additional heating.

Environmental Sustainability: The Green Impact of Low-E Coatings

Low-E coatings play a crucial role in promoting environmental sustainability by significantly reducing energy consumption. By improving the thermal performance of windows, these coatings decrease the need for heating and cooling systems to work overtime. This reduction in energy use directly translates to lower greenhouse gas emissions, contributing to a smaller carbon footprint for both residential and commercial buildings.

In addition to lowering energy consumption, low-E coatings help conserve natural resources. The decreased demand for energy means less reliance on fossil fuels, which are a major source of environmental pollution. This aligns with broader sustainability goals aimed at reducing the impact of human activities on the planet.

Moreover, the use of low-E coatings supports the development of green buildings. These buildings are designed to be energy-efficient and environmentally friendly, and low-E coatings are a key component in achieving these objectives. By incorporating these coatings into window designs, builders and architects can meet stringent energy efficiency standards and contribute to sustainable construction practices.

The environmental benefits of low-E coatings extend beyond individual buildings. On a larger scale, widespread adoption of this technology can lead to significant reductions in overall energy demand. This collective impact supports global efforts to combat climate change and promotes a more sustainable future for all.

Economic Benefits: Long-Term Savings for Homeowners and Businesses

Low-E coatings offer substantial economic benefits by providing long-term energy cost savings for both homeowners and businesses. By enhancing the thermal efficiency of windows, these coatings reduce the need for heating and cooling, leading to lower utility bills. This is particularly advantageous in regions with extreme temperatures, where energy costs can be a significant portion of monthly expenses.

For residential property owners, the initial investment in low-E coatings can be quickly offset by the savings on energy bills. Over time, these savings accumulate, making low-E coatings a cost-effective solution for improving home energy efficiency. Additionally, homes with energy-efficient features, such as low-E windows, often have higher resale values, providing an added financial benefit.

Commercial property owners also stand to gain from the economic advantages of low-E coatings. In large buildings, where heating and cooling costs can be substantial, the energy savings from low-E coatings can be even more pronounced. Businesses can allocate the money saved on energy costs to other operational needs, improving overall financial performance.

The Science Behind Low-E Coatings: How It Works

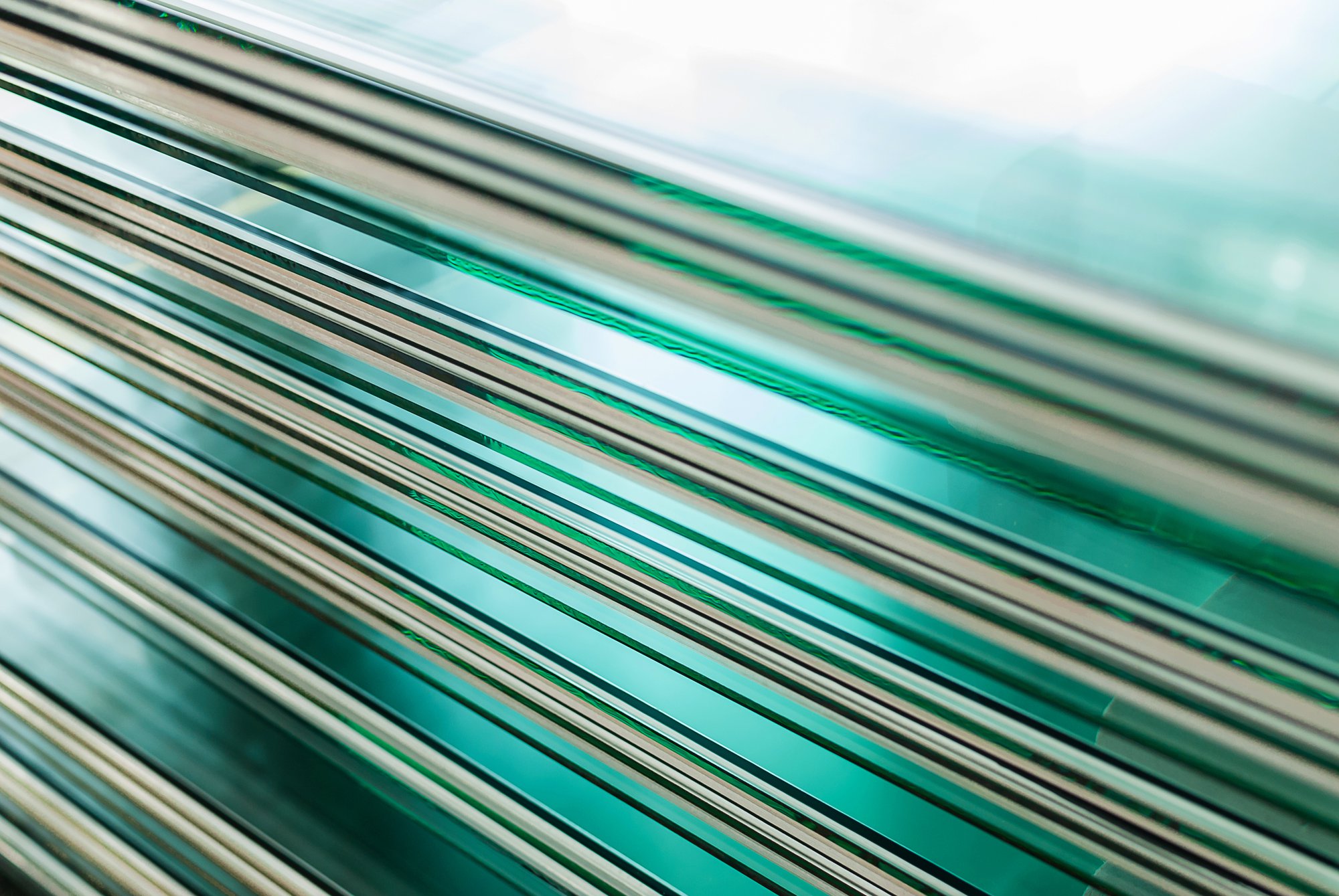

Low-E coatings, or low-emissivity coatings, are thin layers of metallic oxides applied to window glass to enhance thermal insulation. These coatings work by reflecting infrared light, which is responsible for heat transfer. By reflecting this light, low-E coatings help keep heat inside during the winter and outside during the summer, thereby improving the energy efficiency of buildings.

Low-E coatings typically use metals like silver or tin oxide. These metals are chosen for their ability to reflect infrared light while allowing visible light to pass through. This ensures that windows remain clear and transparent, providing natural light without compromising thermal performance.

The effectiveness of low-E coatings lies in their ability to reduce emissivity, which is the measure of a material's ability to emit thermal radiation. Standard glass has a high emissivity, meaning it readily emits heat. Low-E coatings lower this emissivity, reducing the amount of heat that escapes through the glass. This results in better insulation and more stable indoor temperatures.

There are different types of low-E coatings, including hard-coat and soft-coat. Hard-coat low-E coatings are applied during the glass manufacturing process and are more durable, making them suitable for single-pane windows. Soft-coat low-E coatings, on the other hand, are applied after the glass is manufactured and offer better thermal insulation performance. However, they are more delicate and typically used in double—or triple-pane windows.

Investing in Future-Proof Window Technology

Low-E coatings are a game-changer in modern building practices, offering significant benefits in energy efficiency, indoor comfort, environmental sustainability, and long-term cost savings. As we look to the future, investing in low-E coatings represents a smart, sustainable choice for both residential and commercial properties, paving the way for more energy-efficient and environmentally friendly buildings.

Visit Insul-Lite Manufacturing™ for more information on sustainable glass manufacturing and high-quality sealed glass units.