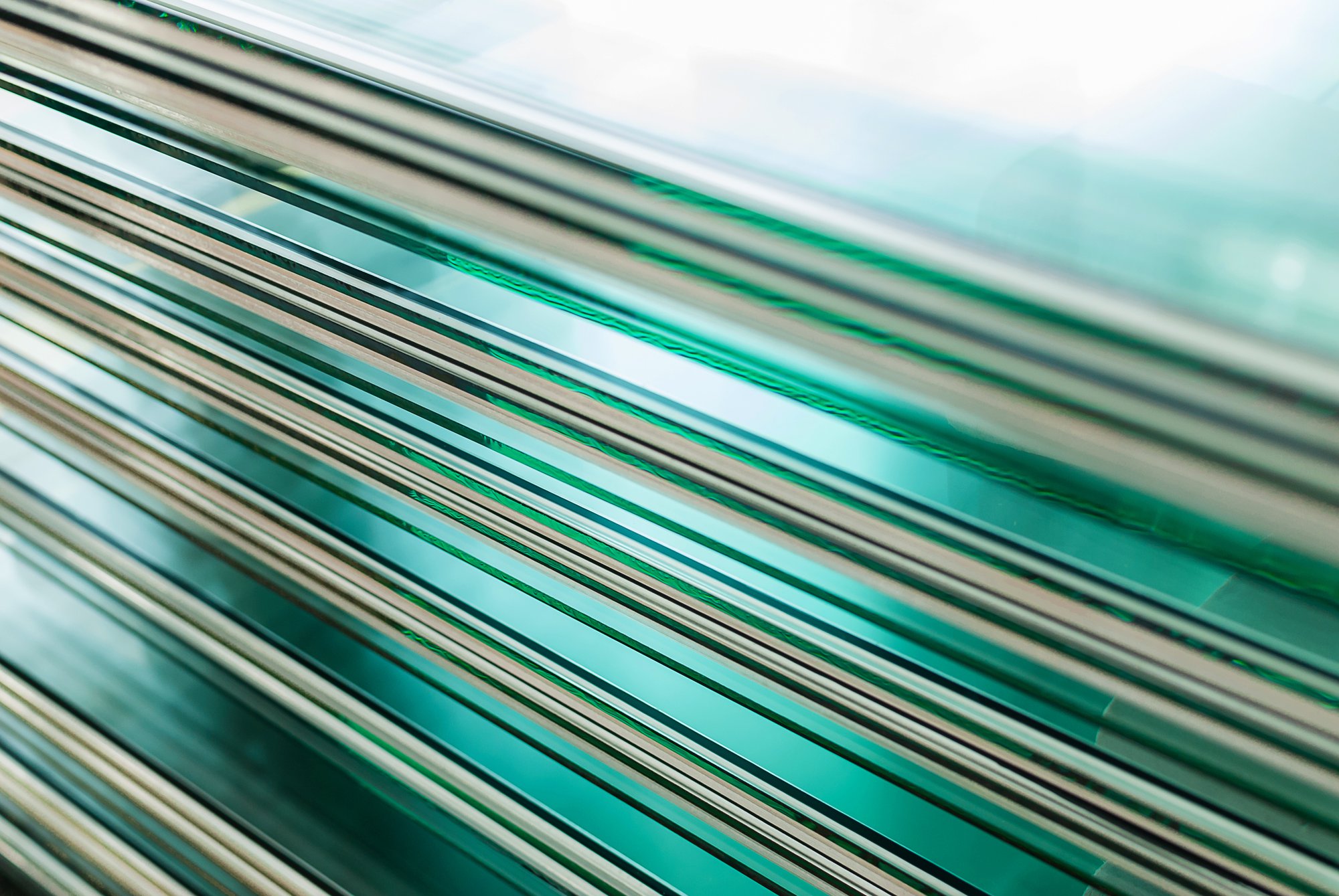

Insulated glass (IG) units are critical for enhancing energy efficiency in modern building designs, helping to regulate indoor climates and reduce energy consumption. These units consist of two or more glass panes, with a spacer between them to create an insulating barrier. The material of the spacer plays a vital role in the overall performance of the IG unit. While aluminum has long been a popular choice, stainless steel spacers offer superior benefits in durability, thermal performance, and long-term sustainability.

These bars are crucial components that enhance both the durability and thermal performance of IG units. By preventing condensation, improving insulation, and reducing energy usage, aluminum spacers contribute significantly to the sustainability of buildings.

The Importance of Stainless Steel in Insulated Glass Units

Stainless steel space bars maintain a consistent gap between glass panes, ensuring optimal insulation and structural integrity. The benefits of using stainless steel over other materials like aluminum or PVC are substantial:

- Improved Thermal Performance: Stainless steel has lower thermal conductivity compared to aluminum, meaning it significantly reduces heat transfer between the panes. This results in better energy efficiency and greater occupant comfort, especially in extreme climates.

- Enhanced Durability: Stainless steel is highly resistant to corrosion, making it a perfect choice for regions with high humidity or extreme temperature fluctuations. The longevity of stainless steel extends the lifespan of IG units, reducing maintenance and replacement costs.

- Condensation Prevention: Stainless steel spacers reduce the risk of condensation forming between the glass panes, which helps prevent fogging and improves the air quality within the building. This is a critical factor in maintaining the clarity and efficiency of IG units over time.

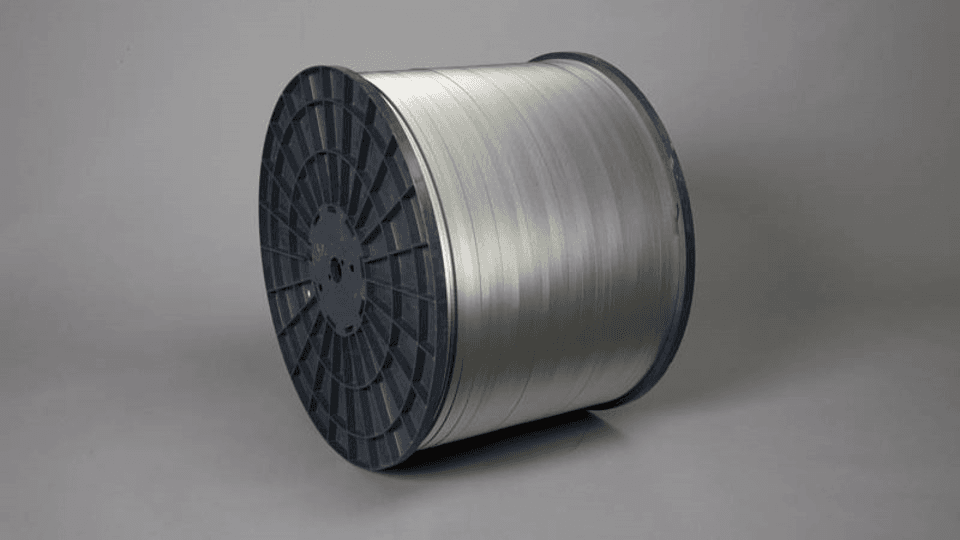

Insul-Lite Manufacturing™ produces space stainless steel spacer bars that outperform conventional materials, offering superior thermal insulation and enhanced durability.

The Science Behind Stainless Steel and Thermal Performance

One of the key advantages of stainless steel is its low thermal conductivity, especially compared to aluminum. This property makes stainless steel space bars far more efficient in insulating buildings and reducing heat loss or gain. Here's how stainless steel spacers contribute to energy efficiency:

- Thermal Bridging Minimization: Unlike aluminum, which can act as a thermal bridge, stainless steel significantly reduces heat transfer, leading to better insulation. This is crucial in maintaining consistent indoor temperatures, reducing the need for excessive heating or cooling.

- Energy Savings: The superior thermal insulation provided by stainless steel spacers ensures that buildings consume less energy, which translates to lower utility bills and a reduced carbon footprint.

This combination of reduced energy consumption and improved occupant comfort makes stainless steel spacers essential for creating sustainable, energy-efficient buildings.

Why Stainless Steel?

While aluminum spacers have been a staple in the industry, stainless steel offers several advantages that make it the superior material for IG units:

- Superior Strength: Stainless steel is incredibly strong yet lightweight, providing both the structural integrity and flexibility needed in construction applications.

- Corrosion Resistance: Unlike aluminum, which can corrode over time in harsh environments, stainless steel remains unaffected, ensuring long-term performance even in extreme weather conditions.

- Better Insulation: While aluminum can lead to thermal bridging, stainless steel minimizes this effect, offering better thermal insulation without compromising the durability of the unit.

In comparison to aluminum and PVC, stainless steel provides a longer lifespan, particularly in regions with extreme temperatures and humidity. By investing in stainless steel, builders and contractors can ensure that their IG units stand the test of time, even in the harshest conditions.

Durability in Extreme Weather Conditions

In regions where temperature fluctuations, humidity, or severe weather are common, such as Alberta and British Columbia, the need for durable materials is paramount. Stainless steel spacers are designed to withstand these conditions by:

- Mitigating Thermal Stress: Stainless steel reduces the risk of thermal stress, which can cause seals in IG units to fail. This ensures long-lasting performance and structural integrity.

- Ensuring Consistent Quality: With stainless steel spacers, IG units can perform reliably over time, even in the most demanding environments.

This durability not only extends the lifespan of IG units but also makes them a more cost-effective and sustainable choice for builders focused on long-term performance.

Innovations in Stainless Steel Spacer Technology

Manufacturers continue to innovate with stainless steel spacers to improve their performance and sustainability. These advancements include:

- Optimized Designs: Stainless steel spacers are now being produced with optimized designs that further enhance thermal performance, pushing the boundaries of energy efficiency.

- Sustainable Practices: Many manufacturers incorporate recycled stainless steel into their production processes, offering a greener solution that aligns with environmental sustainability goals.

These innovations make stainless steel spacers an indispensable component in the construction of energy-efficient, long-lasting IG units.

Building a Sustainable Future with Stainless Steel Spacers

As the construction industry moves toward greener practices, stainless steel spacers have become an essential element in enhancing the durability, thermal performance, and sustainability of IG units. By preventing condensation, improving energy efficiency, and increasing the overall comfort of building occupants, stainless steel spacers are key to achieving sustainable building goals.

Manufacturers dedicated to producing high-quality stainless steel spacers are at the forefront of creating the energy-efficient buildings of the future, ensuring that both performance and sustainability go hand in hand.

Insul-Lite Manufacturing™ remains dedicated to producing the highest-quality space bars, ensuring that future buildings are more energy-efficient, durable, and sustainable. As construction continues to evolve toward greener practices, choosing the right materials is essential–contact us now to learn more!