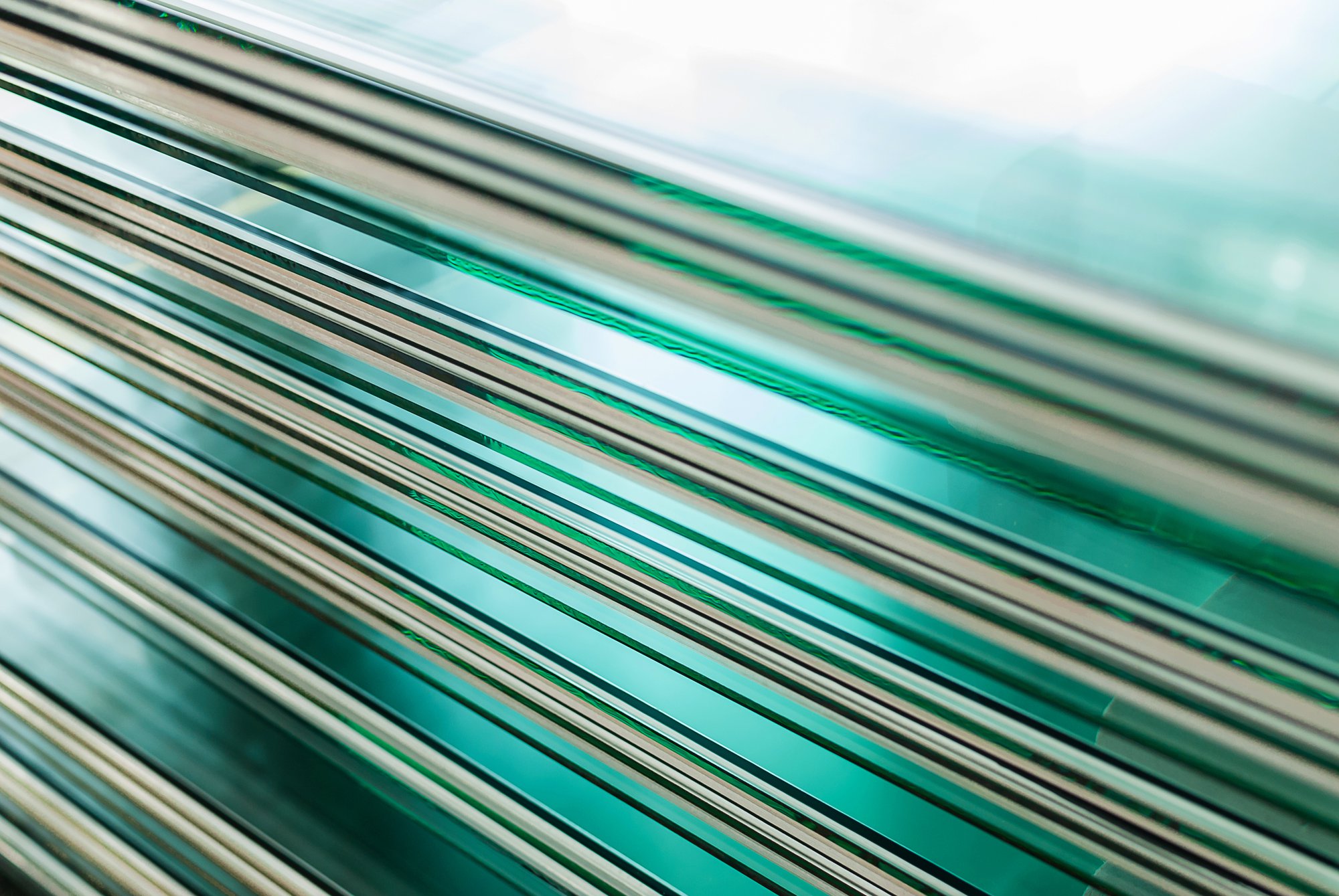

lass products are highly susceptible to damage at every stage of their journey—from manufacturing to transport and installation. Scratches, dust accumulation, and environmental contaminants can compromise both aesthetics and structural integrity. A reliable protective solution is essential to ensure glass reaches its final destination in pristine condition. This is where protective film application becomes indispensable.

Understanding Protective Film Technology

Protective film is a thin, adhesive-backed material applied to glass surfaces to shield them from damage. It is engineered to protect against common risks such as surface abrasions, dirt, and environmental exposure. High-quality polyethylene films, featuring specialized adhesives, adhere securely to glass without leaving any residue upon removal. These films are tailored for different stages of glass handling, including:

- Manufacturing Protection: Prevents scratches and contamination during production.

- Transport Protection: Shields against environmental and mechanical damage during shipping.

- Installation Protection: Ensures glass remains flawless until it is securely placed in its final location.

By integrating protective film application into standard procedures, glass manufacturers can enhance efficiency, minimize defects, and improve overall customer satisfaction.

The Importance of Protective Films in Manufacturing and Transport

Manufacturing Phase

During production, glass undergoes multiple processes that increase its exposure to potential damage. Handling tools, automated machinery, and airborne particles pose a significant risk. Protective films serve as a barrier, preserving the glass's surface integrity throughout fabrication and storage. This proactive approach not only prevents defects but also reduces waste caused by rejections or costly refinishing.

Transport and Logistics

Glass is particularly vulnerable during transport. Changes in temperature, humidity, and mechanical shocks can lead to defects or even breakage. Protective film application ensures that glass remains shielded against such hazards. Key benefits include:

- Scratch Prevention: Reduces the likelihood of handling damage.

- Dust and Contaminant Protection: Maintains cleanliness throughout transit.

- Impact Resistance: Minimizes damage from vibrations and sudden movements.

By utilizing protective films, glass manufacturers and distributors can significantly reduce losses associated with transportation mishaps.

Best Practices for Applying Protective Films

For optimal performance, correct application techniques are crucial. Here are some best practices to ensure effectiveness:

- Surface Preparation: Clean the glass thoroughly to remove dust and debris before applying the film.

- Precise Alignment: Carefully position the film to avoid wrinkles or air pockets.

- Secure Application: Use a squeegee or roller to press the film firmly against the glass.

Proper storage and handling are also essential to maintaining film integrity:

- Avoid Direct Sunlight: Prolonged UV exposure can weaken adhesive properties.

- Stack with Care: Prevent excessive pressure that may compromise adhesion.

- Routine Inspection: Regularly check for film degradation or improper adhesion.

Adhering to these best practices ensures that protective film application delivers maximum benefits throughout the glass-handling process.

The Role of Protective Films in Reducing Costs

Protective films do more than just safeguard glass; they contribute significantly to cost savings in multiple ways. Glass damage during production or transport leads to financial losses due to rework, replacement, and shipping expenses. By implementing protective film application, companies can reduce these costs while maintaining customer satisfaction.

- Minimizing Material Waste: With effective protection, fewer glass units need to be discarded or reprocessed.

- Lowering Labor Costs: Workers spend less time handling damaged products and performing repairs.

- Reducing Insurance Claims: Less damage in transit means fewer claims and lower insurance premiums.

By investing in high-quality protective films, businesses can achieve better financial stability and maintain a competitive edge.

Environmental Considerations in Protective Film Application

As sustainability becomes a priority, the glass industry is shifting towards eco-friendly protective films. Traditional films often contain synthetic materials that contribute to waste accumulation. However, innovations in protective film application are addressing these concerns through:

- Biodegradable Film Options: Designed to break down naturally without harming the environment.

- Recyclable Protective Films: Made from materials that can be repurposed after use.

- Water-Based Adhesives: Reducing the reliance on solvent-based chemicals that may have environmental impacts.

Sustainable protective films allow businesses to maintain high-quality glass protection while aligning with corporate social responsibility initiatives.

Innovations in Protective Film Technology

Recent advancements in protective film technology have improved both durability and performance. These innovations include:

- Enhanced Adhesion: New formulations prevent premature peeling while ensuring residue-free removal.

- UV and Weather Resistance: Films now offer improved resilience against prolonged environmental exposure.

- Eco-Friendly Materials: The development of biodegradable and recyclable films aligns with sustainability goals.

As demand for higher-quality glass products grows, protective films will continue evolving to meet industry needs.

Expanding Applications Beyond Windows

While protective film application is commonly associated with glass windows, its use extends beyond traditional applications. Various industries benefit from protective films, including:

- Automotive Industry: Protecting windshields and glass panels during vehicle assembly and transportation.

- Construction Sector: Temporary protection for glass and mirrors during on-site construction.

- Electronics Manufacturing: Safeguarding delicate glass screens and components.

These diverse applications highlight the versatility of protective films in preserving high-value glass surfaces across different industries.

The Future of Protective Film in the Glass Industry

Looking ahead, protective films will play an increasingly vital role in quality assurance. Emerging trends in protective film application include:

- Biodegradable Protective Films: Reducing environmental impact without compromising performance.

- Smart Films: Innovations that incorporate sensors to monitor handling conditions in real time.

- Custom Solutions: Tailored films designed for specific glass compositions and applications.

Manufacturers investing in these advancements will gain a competitive edge by delivering superior, damage-free glass products.

Safeguarding Glass with Insul-Lite's Protect® Film

Protective films are not just an industry standard; they are a necessity for ensuring glass reaches its destination in flawless condition. Insul-Lite offers a high-performance solution with Protect® Film, designed to safeguard glass throughout manufacturing, transportation, and installation.

By integrating Protect® Film into your production and handling processes, you can enhance product durability, reduce costly damages, and deliver superior quality to your customers. Don’t leave your glass vulnerable to preventable damage—contact Insul-Lite Manufacturing to learn more about how our Protect® Film can elevate your glass protection strategy.