Tempered safety glass is a cornerstone of modern architecture and design, renowned for its exceptional strength and safety features. Through a specialized thermal treatment, this glass type is engineered to withstand significant stress and, when broken, disintegrates into small, less harmful fragments. Its unique properties make it indispensable in various applications, from residential spaces to commercial structures.

What Makes Tempered Safety Glass Different?

Tempered safety glass undergoes a rigorous manufacturing process that significantly enhances its durability compared to standard glass. This process involves heating the glass to approximately 620°C (1,148°F) and then rapidly cooling it. This rapid cooling, or quenching, induces compressive stresses on the surface and tensile stresses in the interior, resulting in a glass that is up to five times stronger than its annealed counterpart. Moreover, when tempered glass breaks, it fractures into small, blunt pieces, reducing the risk of injury—a critical safety feature in many applications.

Key Benefits of Tempered Safety Glass

Enhanced Strength and Durability

The tempering process imbues the glass with superior strength, making it resistant to impacts, scratches, and thermal stresses. This robustness ensures longevity and reduces the frequency of replacements, offering both safety and economic benefits.

Safety Through Controlled Fragmentation

In the event of breakage, tempered safety glass crumbles into small, rounded pieces rather than sharp shards. This characteristic minimizes the potential for serious injuries, making it an ideal choice for environments where human safety is a priority.

Thermal Resistance

Tempered glass can withstand significant temperature variations, making it suitable for applications exposed to extreme heat or cold. Its ability to endure thermal stress without cracking is advantageous in both residential and commercial settings.

Versatility in Application

The combination of strength, safety, and aesthetic appeal allows tempered safety glass to be used in a wide array of applications, from structural components to decorative elements.

Common Applications of Tempered Safety Glass

Residential and Commercial Architecture

In both homes and commercial buildings, tempered safety glass is utilized for windows, doors, and skylights. Its strength and safety features make it ideal for areas prone to impact or requiring enhanced security.

Shower Enclosures and Bathroom Fixtures

Tempered glass is the preferred material for shower doors and enclosures due to its resistance to moisture and thermal changes. Its safety characteristics also provide peace of mind in environments where slips and falls are common.

Furniture and Interior Design

From sleek tabletops to elegant shelving units, tempered safety glass combines functionality with aesthetics. Its ability to support weight and resist scratches makes it a popular choice in modern interior design.

Automotive Industry

In vehicles, tempered glass is commonly used for side and rear windows. Its strength provides protection, and in the event of an accident, it breaks into small pieces, reducing the risk of injury to passengers.

The Manufacturing Process of Tempered Safety Glass

The production of tempered safety glass involves several critical steps to ensure its enhanced properties:

- Cutting and Shaping: The glass is cut to the desired dimensions and edges are finished before the tempering process begins.

- Heating: The glass is heated uniformly in a furnace to temperatures exceeding 600°C (1,112°F).

- Quenching: Immediately after heating, the glass is rapidly cooled using high-pressure air blasts. This rapid cooling solidifies the outer surfaces while the interior remains in tension, creating the balanced stress profile that gives tempered glass its strength.

It's important to note that any cutting or drilling must be performed before the tempering process, as attempting modifications afterward can cause the glass to shatter.

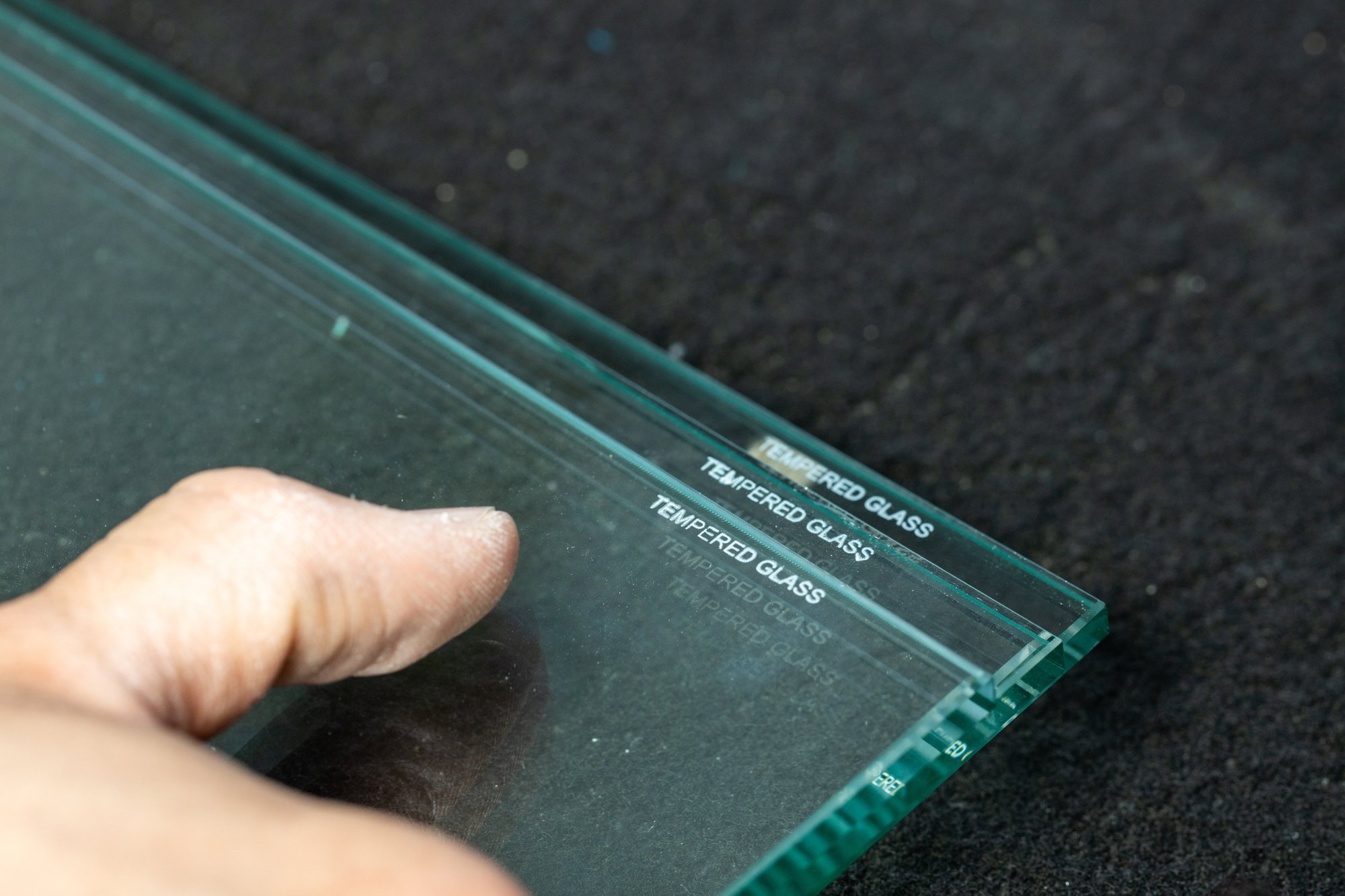

Quality Assurance in Tempered Safety Glass Production

Ensuring the quality of tempered safety glass is paramount, as its performance directly impacts safety and durability. Manufacturers adhere to stringent industry standards and conduct rigorous testing to verify attributes such as strength, clarity, and fragmentation pattern upon breakage. Regular inspections and quality control measures throughout the manufacturing process help maintain consistency and reliability in the final product.

Advancements in Tempered Safety Glass Technology

The field of tempered safety glass is continually evolving, with innovations aimed at enhancing its properties and expanding its applications:

- Energy Efficiency: Developments in coatings and treatments have led to tempered glass options that improve thermal insulation, contributing to energy savings in buildings.

- Smart Glass Integration: Combining tempered glass with smart technologies allows for features like adjustable transparency and solar control, increasing functionality in both residential and commercial settings.

- Improved Acoustic Performance: Innovations in lamination and layering techniques have enhanced the soundproofing capabilities of tempered glass, making it more effective in noise reduction applications.

Choosing the Right Tempered Safety Glass for Your Needs

Selecting the appropriate tempered safety glass involves considering factors such as thickness, size, and any additional treatments or coatings required for specific applications. Consulting with experienced manufacturers can provide valuable insights into the best options to meet structural and aesthetic requirements.

Invest in Safety and Quality with Insul-Lite

Tempered safety glass stands as a testament to the advancements in material science, offering a blend of strength, safety, and versatility. Its widespread use across various industries underscores its importance in creating secure and resilient environments.

At Insul-Lite, we are committed to delivering high-quality tempered safety glass products that meet the diverse needs of our clients. As a leading wholesale sealed unit manufacturer, we supply lites and custom sealed units to window manufacturers, glazing contractors, and glass shops. Our dedication to excellence ensures that our tempered glass solutions provide the reliability and performance your projects demand.

Contact Insul-Lite to learn more about how our tempered safety glass products can enhance the safety and aesthetics of your next project.