Building codes are designed to ensure safety and structural integrity, guiding construction projects to meet regulatory requirements. Among these essential components, safety glass plays a critical role in protecting occupants from impact-related injuries, reducing hazards in the event of breakage, and enhancing overall building performance. Compliance with safety glass regulations is not just about meeting industry standards—it’s about creating safer, more resilient structures.

Understanding Industry Standards for Safety Glass

Safety glass is regulated by strict industry standards established by organizations such as ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute). These standards ensure that safety glass products meet specific performance criteria to protect occupants and enhance structural integrity in buildings.

Key Safety Glass Standards

- ASTM C1048: Specifies requirements for heat-treated flat glass, including tempered glass.

- ANSI Z97.1: Defines the safety performance of architectural glass, covering impact resistance and breakage patterns.

- ASTM E1300: Provides guidelines for determining the load resistance of glass used in buildings.

Adhering to these standards ensures that safety glass products maintain consistent quality and meet the necessary safety regulations for a variety of applications.

Types of Safety Glass and Their Compliance

Different types of safety glass are designed to meet specific industry standards and fulfill unique roles in construction. Selecting the right type depends on factors such as impact resistance, thermal performance, and regulatory requirements.

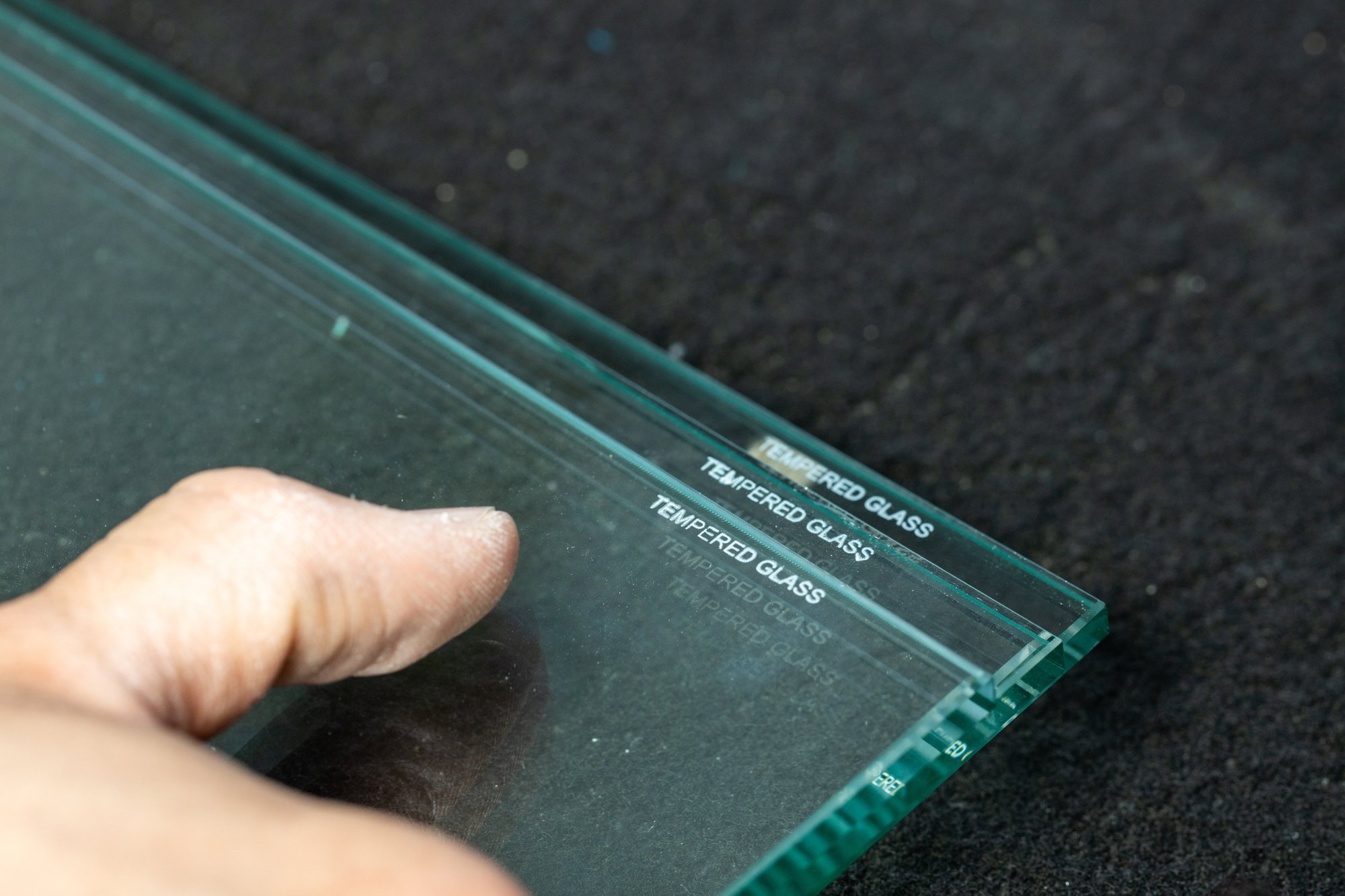

Tempered Glass

Tempered glass is created through a controlled heat treatment process, making it significantly stronger than standard glass. When broken, it shatters into small, blunt pieces, reducing the risk of injury. It complies with ASTM C1048 and is commonly used in high-impact areas such as shower doors, glass railings, and storefronts.

Laminated Glass

Laminated glass consists of multiple layers of glass bonded together with an interlayer, typically made of polyvinyl butyral (PVB). This structure holds the glass in place upon impact, preventing shattering and reducing the risk of injury. It meets ANSI Z97.1 standards and is frequently used in skylights, automobile windshields, and security applications.

Insulated Glass Units (IGUs)

Insulated glass units (IGUs) consist of two or more panes of glass separated by a spacer and sealed to create an insulating airspace. They comply with ASTM E1300 and are essential for improving energy efficiency, reducing heat transfer, and enhancing indoor comfort. IGUs are widely used in windows and curtain walls for both residential and commercial buildings.

Each of these safety glass types serves a distinct purpose while meeting strict ASTM and ANSI requirements, ensuring reliability across various architectural applications.

Best Practices for Selecting Safety Glass

Choosing the appropriate type of safety glass for a construction project requires careful consideration of several factors:

- Assess Environmental Conditions: Consider exposure to wind loads, seismic activity, and potential impact hazards.

- Determine the Application: Identify whether the glass will be used in doors, windows, partitions, or specialty areas, as this influences the necessary safety features.

- Ensure Compliance with Regulations: Check local building codes and regulations that dictate specific safety glass requirements.

Consulting with manufacturers and industry experts can provide valuable insights into the latest safety glass technologies, ensuring optimal performance and compliance.

The Role of Quality Manufacturers in Safety Glass Compliance

Partnering with reputable manufacturers is essential for sourcing high-quality safety glass that meets industry standards. Manufacturers with extensive experience in safety glass production ensure that products are rigorously tested for durability, impact resistance, and energy efficiency.

When evaluating manufacturers, consider:

- Industry Certifications: Ensure the manufacturer’s products are tested and certified according to ASTM and ANSI standards.

- Product Customization: Look for options that can be tailored to specific project requirements.

- Technical Support: A manufacturer with strong customer service and technical support can help with compliance and product selection.

Working with a trusted manufacturer simplifies the process of selecting and integrating safety glass into construction projects while ensuring regulatory compliance.

Future Developments in Safety Glass Standards

As technology and safety requirements evolve, advancements in safety glass production continue to shape the industry. Key trends include:

- Smart Glass Innovations: Self-tinting and electrochromic glass technologies that enhance energy efficiency and privacy control.

- Improved Strength and Durability: Advancements in manufacturing techniques that produce glass with increased impact resistance and longevity.

- Sustainable Materials: The development of eco-friendly safety glass solutions that minimize environmental impact while maintaining high performance.

Staying informed about these innovations ensures that architects, builders, and glazing professionals can incorporate the latest safety glass advancements into their projects.

Enhancing Safety and Performance with Insul-Lite

Selecting the right safety glass is critical for meeting building code requirements and ensuring long-term durability. At Insul-Lite, we specialize in high-performance insulated glass units (IGUs) and custom sealed units designed to meet stringent safety standards. Our commitment to quality and innovation ensures that our products not only comply with ASTM and ANSI requirements but also provide enhanced energy efficiency and durability for modern construction projects.

For high-quality safety glass solutions that meet industry standards, contact us today.