How can the window manufacturing industry reduce its environmental impact while maintaining quality and efficiency? The urgency of sustainability in window manufacturing cannot be overstated. As environmental concerns grow, the industry faces increasing pressure to adopt eco-friendly practices. This article explores the cutting-edge materials and processes transforming window manufacturing, aiming to balance environmental responsibility with operational excellence.

Environmental Impact of Traditional Window Manufacturing

Traditional window manufacturing practices significantly impact the environment. The industry generates substantial waste, including glass offcuts, metal scraps, and packaging materials. These byproducts often end up in landfills, contributing to environmental degradation.

Energy consumption is another critical issue. Conventional manufacturing processes require high energy inputs, primarily from non-renewable sources. This results in a considerable carbon footprint. For instance, the production of one square meter of glass can emit up to 25 kg of CO2.

Moreover, the use of non-sustainable materials exacerbates the problem. Many traditional windows incorporate materials that are not recyclable or biodegradable, further straining natural resources and increasing the industry's overall environmental impact.

Emerging Eco-Friendly Materials

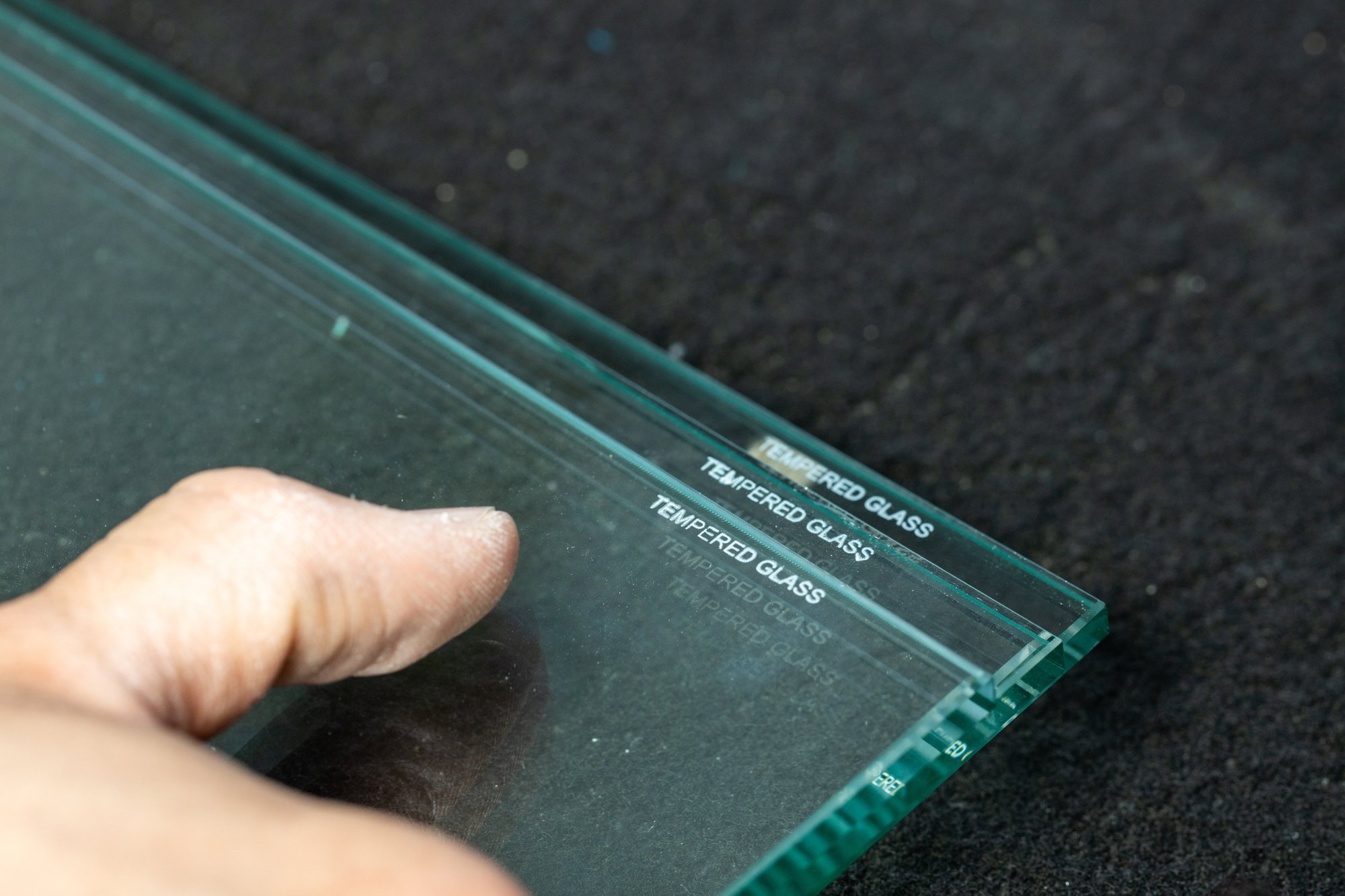

Innovative materials are transforming window manufacturing. Low-emissivity (Low-E) glass is a prime example. This glass type reduces heat transfer, improving energy efficiency. It helps maintain indoor temperatures, reducing the need for heating and cooling. Consequently, it lowers energy consumption and greenhouse gas emissions.

Recycled content frames are another eco-friendly option. Manufacturers use materials like reclaimed aluminum and recycled PVC. These frames reduce the demand for virgin resources. They also minimize waste, as they can be recycled at the end of their lifecycle. This approach supports a circular economy, promoting sustainability.

Energy-Efficient Manufacturing Processes

Advancements in manufacturing processes are crucial for energy efficiency. Automated production lines streamline operations, reducing energy consumption. These systems optimize resource use, minimizing waste and improving precision. For example, automated glass cutting reduces material waste by up to 20%.

Smart factory technologies further enhance efficiency. These systems use sensors and data analytics to monitor and control energy use. They adjust operations in real time, ensuring optimal performance. According to industry reports, this approach can reduce energy consumption by up to 30%.

Regulatory and Industry Standards

Regulations and industry standards play a pivotal role in promoting sustainable practices in window manufacturing. Policies like LEED (Leadership in Energy and Environmental Design) set benchmarks for eco-friendly construction. LEED certification encourages the use of energy-efficient windows, driving manufacturers to adopt sustainable materials and processes.

ENERGY STAR is another critical certification. This program identifies products that meet strict energy efficiency guidelines. Windows with the ENERGY STAR label must meet specific criteria for thermal performance and insulation. This certification helps consumers make informed choices, pushing manufacturers to improve their products.

Several countries have implemented regulations to support these standards. In the U.S., the Energy Policy Act mandates energy efficiency in building materials, including windows. The European Union's Energy Performance of Buildings Directive sets similar requirements. These regulations ensure that manufacturers prioritize sustainability.

Industry standards also foster innovation. The National Fenestration Rating Council (NFRC) provides performance ratings for windows. These ratings include U-factor, solar heat gain coefficient, and visible transmittance. By adhering to these standards, manufacturers can improve product performance and reduce environmental impact.

Future Trends in Sustainable Window Manufacturing

Future trends in window manufacturing promise further sustainability. Advancements in material science are at the forefront. Researchers are developing new composites that offer superior insulation and durability. These materials reduce energy loss and extend the lifespan of windows, minimizing waste.

Increased automation will also play a significant role. Smart factories will become more prevalent, utilizing AI and IoT technologies. These systems will optimize production processes, reducing energy consumption and material waste. Predictive maintenance will ensure machinery operates efficiently, further cutting down on resource use.

Nanotechnology is another exciting development. Coatings with nanomaterials can enhance glass properties, such as self-cleaning and UV protection. These innovations improve window performance and reduce the need for chemical cleaners, benefiting the environment.

Moving Forward Towards a Greener Future

Reducing the environmental impact of window manufacturing is crucial. Traditional practices generate waste and consume significant energy. However, innovative materials like Low-E glass and recycled frames offer sustainable alternatives. Continued innovation and adherence to these practices are essential for a greener future in window manufacturing.

Visit Insul-Lite Manufacturing™ to explore a range of eco-friendly glass products.