How do argon gas windows contribute to sustainable building practices? Argon gas, a colorless and odorless noble gas, is increasingly used in modern windows to enhance insulation. By filling the space between double or triple panes, argon gas significantly reduces heat transfer, leading to improved energy efficiency and lower utility bills. This innovative approach supports eco-friendly construction and plays a crucial role in achieving green building certifications.

The Science Behind Argon Gas Insulation

Due to its unique physical properties, argon gas is a key player in window insulation. As a noble gas, argon is denser than air, which means it has a lower thermal conductivity. This density reduces the amount of heat that can pass through the window, making it an excellent insulator. When used in double or triple-pane windows, argon gas fills the space between the panes, creating a barrier that minimizes heat transfer.

The principles of heat transfer reduction are straightforward. Heat moves from warmer areas to cooler ones through conduction, convection, and radiation. Argon gas, with its low thermal conductivity, slows down this process. By reducing the rate at which heat escapes or enters a building, argon gas windows help maintain a consistent indoor temperature. This not only enhances comfort but also reduces the need for heating and cooling, leading to energy savings.

Furthermore, argon gas is non-reactive and non-toxic, making it a safe choice for residential and commercial buildings. Its inert nature ensures that it does not corrode or damage the window materials over time. This stability contributes to the long-term effectiveness of argon gas windows, providing a reliable solution for improved insulation and energy efficiency.

Energy Efficiency and Cost Savings

Argon gas windows significantly enhance energy efficiency by reducing the amount of heat that escapes during winter and enters during summer. This improved insulation leads to a more stable indoor temperature, which reduces the need for constant heating and cooling. As a result, homeowners and businesses can see a noticeable decrease in their utility bills. For instance, studies have shown that buildings with argon gas windows can achieve energy savings of up to 20% compared to those with standard windows.

Several case studies highlight the cost-saving benefits of argon gas windows. One notable example is a commercial building retrofit project in Chicago, where the installation of argon-filled double-pane windows resulted in a 15% reduction in annual energy costs. Another study by the National Renewable Energy Laboratory (NREL) found that homes with argon gas windows experienced a 10-15% decrease in heating and cooling expenses.

Industry reports also support these findings. According to the U.S. Department of Energy, argon gas windows are among the most effective solutions for improving building energy performance. The Energy Star program, which certifies energy-efficient products, often recommends argon-filled windows for both residential and commercial applications. These endorsements underscore the substantial impact that these windows can have on reducing energy consumption and lowering operational costs.

Environmental Benefits of Argon Gas Windows

Argon gas windows play a crucial role in promoting sustainability by significantly reducing carbon footprints. By enhancing insulation and improving energy efficiency, these windows lower the demand for heating and cooling systems, which in turn reduces greenhouse gas emissions. Buildings equipped with these windows consume less energy, leading to a decrease in the burning of fossil fuels and a corresponding reduction in carbon dioxide output.

These windows also contribute to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). LEED certification recognizes buildings that implement sustainable practices, and energy-efficient windows are a key component of this. Argon gas windows help buildings earn points in the energy and atmosphere category, which is critical for obtaining higher certification levels. This not only benefits the environment but also enhances the marketability and value of the property.

In addition, these windows align with eco-friendly construction practices. They support the goals of sustainable architecture by minimizing energy consumption and promoting the use of non-toxic, inert materials. Builders and developers who prioritize green construction often choose argon gas windows to meet stringent environmental standards. This choice reflects a commitment to reducing environmental impact and promoting long-term sustainability in the built environment.

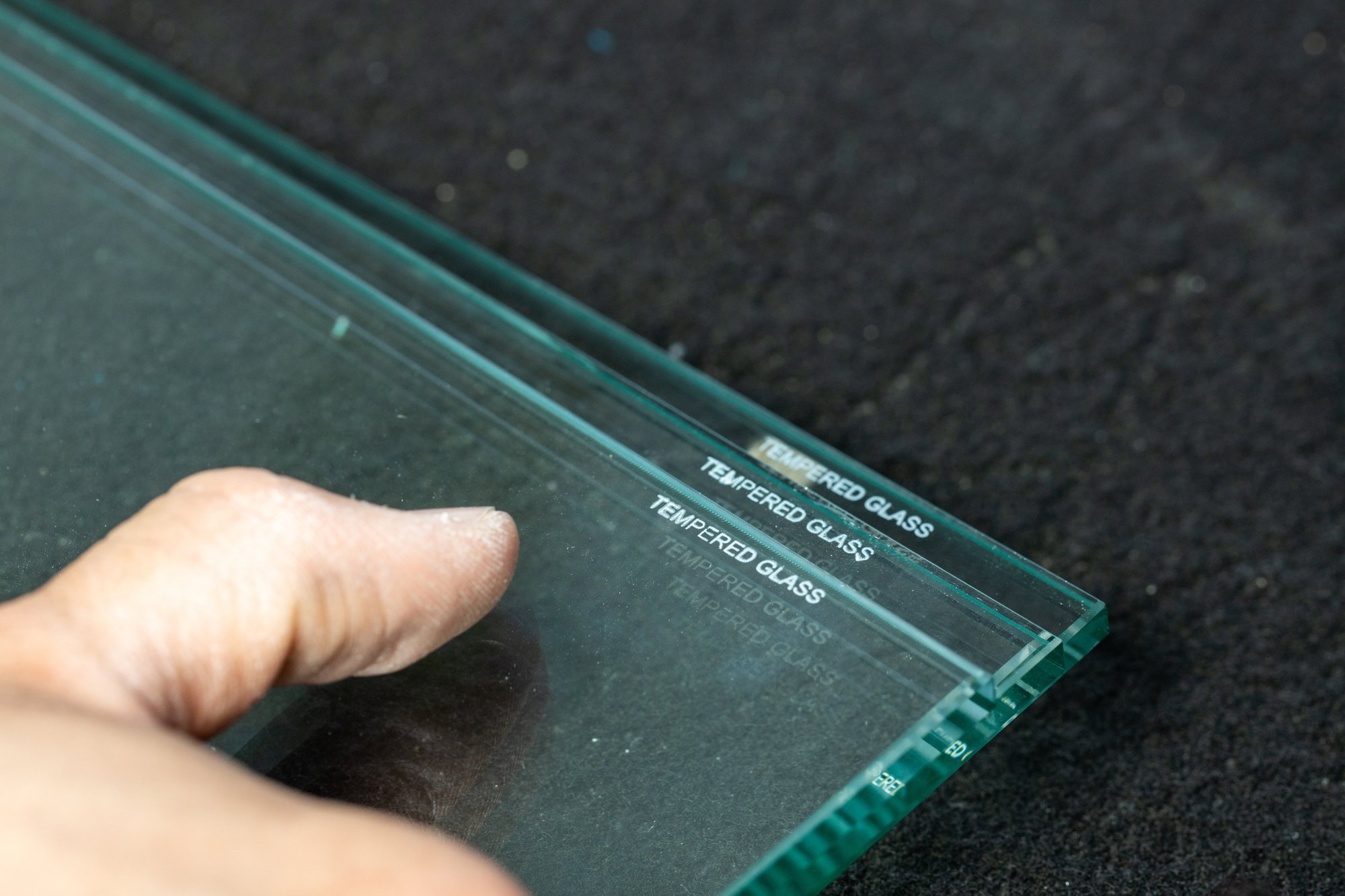

Installation and Maintenance Considerations

Installing argon gas windows requires careful attention to detail to ensure optimal performance. Proper sealing is crucial; any gaps or leaks can compromise the insulating properties of the argon gas. It is essential to work with experienced installers who understand the specific requirements of argon-filled windows. They should use high-quality sealants and ensure that the window frames are correctly aligned to prevent any gas leakage.

Maintenance of this window type is relatively straightforward but should not be overlooked. Regular inspections can help identify any potential issues early. Look for signs of condensation between the panes, which may indicate a seal failure. If condensation is present, it is important to address it promptly to maintain the window's insulating properties. Cleaning the windows with non-abrasive cleaners will also help preserve the integrity of the seals.

Best practices for maintaining argon gas windows include:

- Regular Inspections: Check for any signs of seal failure or condensation.

- Proper Cleaning: Use non-abrasive cleaners to avoid damaging the seals.

- Professional Maintenance: Schedule periodic professional inspections to ensure the windows remain in optimal condition.

Potential challenges include the initial cost of installation and the need for specialized installers. However, the long-term energy savings and environmental benefits often outweigh these initial investments. By following these best practices and addressing any issues promptly, homeowners and businesses can ensure that their windows provide effective insulation and energy efficiency for many years.

Future Trends and Innovations in Window Insulation

Emerging trends in window insulation technology continue to push the boundaries of energy efficiency and sustainability. Innovations such as multi-layered argon gas windows and the integration of smart window technologies are set to revolutionize the industry. These advancements promise even greater reductions in heat transfer and improved indoor climate control. Additionally, the development of more cost-effective manufacturing processes for argon gas windows will make them accessible to a broader market. As these technologies evolve, the role of argon gas in sustainable building practices will only grow stronger, offering enhanced performance and further reducing environmental impact. For more information, visit Insul-Lite Manufacturing™.