Low-E glass, short for low-emissivity glass, is a high-performance solution that enhances energy efficiency while maintaining aesthetic appeal. With a thin layer of low-e coating, this specialized glass reflects infrared heat while allowing visible light to pass through, helping to regulate indoor temperatures and reduce energy costs. As sustainability and energy efficiency become key priorities in modern construction, Low-E glass is an essential component for high-performance buildings.

Understanding Low-E Glass and Its Role in Energy Efficiency

Low-E glass is engineered with a microscopically thin metal oxide layer that minimizes heat transfer while maximizing natural light. This coating significantly improves a building’s insulation properties, making indoor spaces more comfortable year-round. Whether used in residential or commercial settings, low-e coating plays a vital role in reducing energy consumption and enhancing occupant comfort.

How Low-E Coatings Work

The low-e coating on glass works by reflecting heat back to its source. In the winter, it prevents indoor heat from escaping, keeping interiors warm. In the summer, it reflects exterior heat, keeping spaces cooler. This process helps maintain a stable indoor climate, reducing reliance on HVAC systems and lowering energy bills.

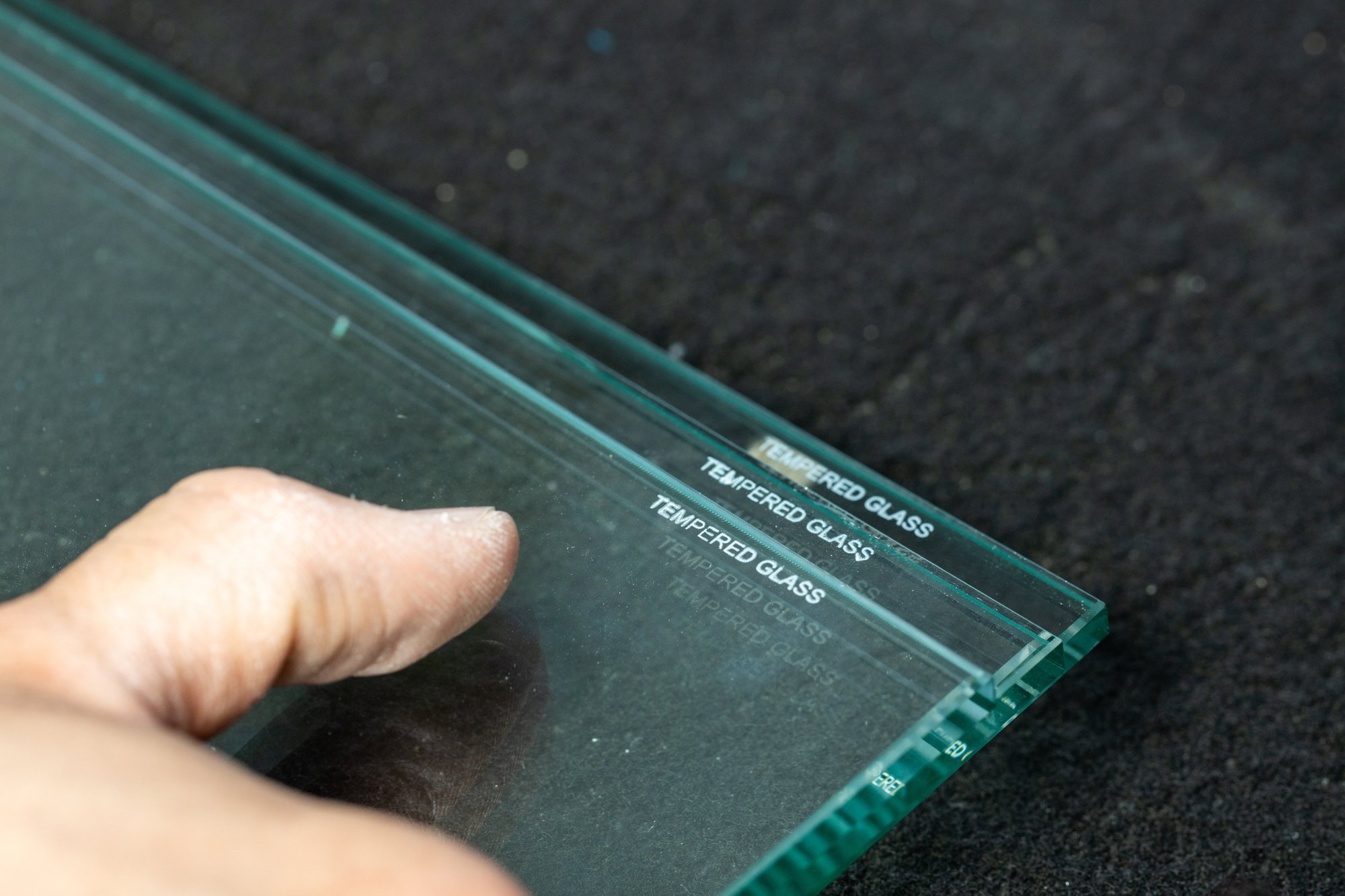

There are two primary types of Low-E glass:

- Soft-Coat Low-E Glass: Offers superior thermal insulation and is ideal for residential applications where energy efficiency is a priority.

- Hard-Coat Low-E Glass: Provides increased durability, making it suitable for commercial buildings and projects requiring structural resilience.

Choosing the right type of low-e coating depends on the specific energy efficiency needs and performance requirements of a building.

Types of Low-E Coatings and Their Applications

Beyond soft-coat and hard-coat options, Low-E coatings are categorized based on their solar control properties:

- High Solar Gain Low-E Coatings: These coatings allow more solar heat to enter a space, making them ideal for colder climates where passive solar heating can reduce heating costs.

- Moderate Solar Gain Low-E Coatings: A balanced option that provides insulation benefits while still allowing some solar heat gain, suitable for mixed climates.

- Low Solar Gain Low-E Coatings: Designed to minimize heat gain, these coatings are best suited for warmer climates where cooling costs are a primary concern.

By selecting the appropriate low-e coating, architects and builders can optimize energy performance based on climate and building orientation.

The Benefits of Low-E Glass in Modern Buildings

Improved Indoor Comfort

One of the biggest advantages of Low-E glass is its ability to create a more comfortable indoor environment. By minimizing heat transfer, it helps maintain consistent temperatures, reducing cold drafts in winter and excessive heat buildup in summer.

- Regulates indoor temperatures year-round

- Reduces reliance on heating and cooling systems

- Minimizes temperature fluctuations for greater comfort

This improvement in thermal performance contributes to a healthier and more enjoyable living or working space.

Reduced Energy Costs

By limiting heat loss and heat gain, Low-E glass reduces the energy needed to maintain a comfortable indoor temperature. This translates into significant cost savings for property owners.

- Lowers monthly energy bills

- Reduces HVAC system workload, extending equipment lifespan

- Improves overall building energy efficiency

For commercial buildings, these savings can be substantial, making low-e coating a smart investment in long-term cost reduction.

Protection Against UV Rays

Low-E glass also provides superior protection against ultraviolet (UV) radiation, which can cause fading and damage to furniture, flooring, and artwork.

- Blocks up to 99% of harmful UV rays

- Preserves interior furnishings and decor

- Enhances occupant well-being by reducing UV exposure

This added benefit makes Low-E glass an excellent choice for spaces with large windows or extensive glass facades.

Sustainability and Environmental Impact

Energy Efficiency and Carbon Footprint Reduction

The use of Low-E glass contributes to sustainable building design by reducing overall energy consumption. By lowering heating and cooling demands, buildings equipped with low-e coating help decrease greenhouse gas emissions.

- Supports green building certifications like LEED

- Aligns with energy efficiency regulations and standards

- Reduces dependency on fossil fuel-based energy sources

As global efforts to combat climate change intensify, incorporating Low-E glass into modern buildings is an effective way to promote environmental responsibility.

Contribution to Green Building Design

Low-E glass is widely used in projects aiming for energy efficiency and sustainability. Its ability to optimize indoor climates without compromising aesthetics makes it a key component in green architecture.

- Facilitates natural daylighting without excessive heat gain

- Enhances passive solar heating in colder climates

- Improves overall building envelope performance

By integrating Low-E glass, architects and builders can meet modern energy efficiency standards while maintaining design flexibility.

Long-Term Value and Cost Savings

Lower Maintenance and Extended Lifespan

Investing in Low-E glass offers long-term financial benefits beyond immediate energy savings. Since it reduces strain on HVAC systems and enhances insulation, buildings require less maintenance over time.

- Minimizes wear and tear on heating and cooling equipment

- Prevents condensation-related issues, reducing repair costs

- Ensures consistent performance over decades

These factors contribute to a lower total cost of ownership for property owners, making low-e coating a cost-effective choice.

Increased Property Value

Energy-efficient upgrades like Low-E glass can increase a property’s market value. Buildings with enhanced thermal performance and sustainability features are more attractive to buyers and tenants.

- Improves resale value for residential properties

- Enhances appeal for commercial tenants seeking energy-efficient spaces

- Provides a competitive edge in the real estate market

The demand for energy-efficient buildings is rising, and incorporating Low-E glass is a strategic move to future-proof properties against evolving industry standards.

Industry Applications of Low-E Glass

Low-E glass is widely used in various sectors, including:

- Residential homes: Enhancing energy efficiency in windows, patio doors, and skylights.

- Commercial buildings: Improving sustainability in office towers, retail spaces, and industrial facilities.

- Healthcare facilities: Reducing glare and improving thermal comfort in hospitals and clinics.

- Educational institutions: Creating well-lit and energy-efficient learning environments.

Its versatility makes low-e coating a valuable asset in virtually any construction project.

Elevate Your Projects with Insul-Lite

For high-performance Low-E glass solutions, Insul-Lite delivers industry-leading quality and innovation. As a premier wholesale sealed unit manufacturer, we supply lites and custom sealed units to window manufacturers, glazing contractors, and glass shops. Our advanced low-e coating technology enhances energy efficiency, comfort, and sustainability in modern buildings.

Upgrade your glass solutions with Insul-Lite. Contact us to learn how our premium sealed units can enhance your next project.